We're professional multiclone dust collector manufacturers and suppliers in China, to buy or wholesale multi tube impact dust collector from our factory. For quotation or if you have any questions, contact us now for customized multiclone dust collector and price.

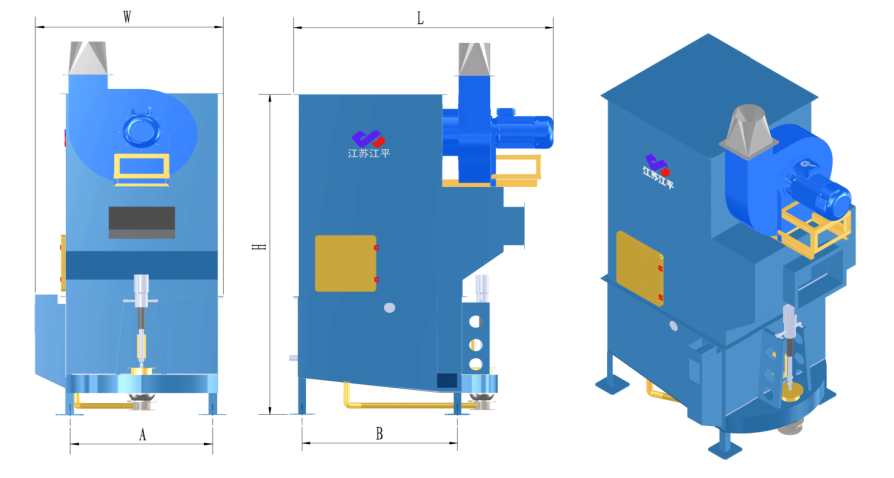

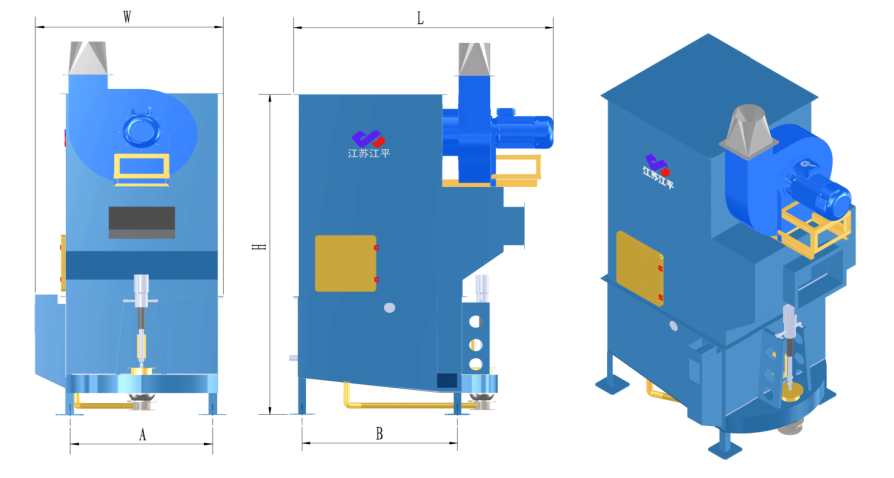

Appearance Reference

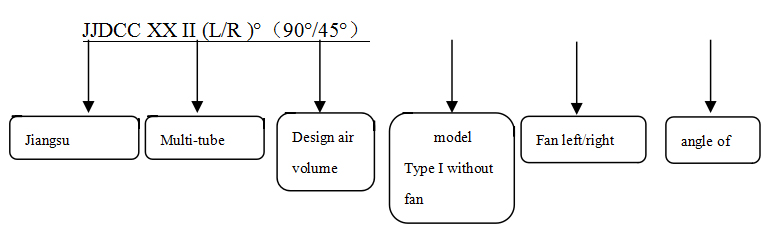

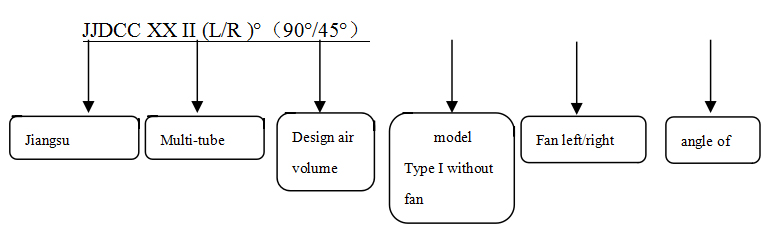

Symbol standard of multiclone dust collector

Features

Suitable for flammable and explosive dust.

Working Principle

The dust collector is divided into an upper box and a lower box. The upper box includes: air inlet and outlet, distribution air supply pipe, two water baffles, spray head (ABS) and centrifugal fan. (JJDCC-19, 24 and 33 dust collectors do not include centrifugal fans)

The lower box body includes: mud bucket, water spray pipe, etc. The dust collector is additionally equipped with: electric push rod, liquid level controller, electromagnetic valve, etc. After the dust-bearing gas enters from the inlet, the larger dust particles are blocked by the ash baffle and are removed, and the smaller dust particles enter the header together with the airflow. At this time, the dust-bearing gas passes through the air supply pipe and is ejected from the nozzle at a high speed, impacting the liquid surface and bumping up a large number of bubbles and water droplets, so as to achieve the purpose of purifying the air. The purified air is discharged from the air outlet (or the air outlet of the centrifugal fan) through the first water baffle and the second water baffle under the action of the centrifugal fan. The purified sewage with gas and dust is discharged through the drainage outlet. When the sewage is basically discharged, the electromagnetic valve of the water level controller on the water inlet main pipe is opened (the water supply pressure is 0.4-0.6MPa), and the water is sprayed through the water inlet pipe by the flushing nozzle at the lower part of the dust collector box, so as to flush the bottom of the box, and then the piston is lowered by the electric push rod, and the drainage outlet is closed; The water level in the box body rises; When the water level rises to the height required for dust removal, the electromagnetic valve of the water level controller is closed to stop the water, and the excess water in the box is discharged from the overflow pipe. At this time, the dust collector can enter the working state.

Technical parameters of multiclone dust collector

Product Model | JPCDCC-4-Ⅱ | JPCDCC-7-Ⅱ | JPCDCC-11-Ⅱ | JPCDCC-14-Ⅱ | JPCDCC-19-Ⅰ | JPCDCC-24-Ⅰ | JPCDCC-33-Ⅰ |

Nozzle Velocity (m/s) | 8 | 10 | 12 | 8 | 10 | 12 | 8 | 10 | 12 | 8 | 10 | 12 | 8 | 10 | 12 | 8 | 10 | 12 | 8 | 10 | 12 |

Design Airflow (m³/h) | 3840 | 4800 | 5750 | 5760 | 7200 | 8640 | 8640 | 10800 | 12960 | 10800 | 11520 | 14400 | 15360 | 17280 | 19200 | 19200 | 23040 | 24000 | 26800 | 28800 | 33600 |

Equipment Resistance (Pa) | 1600-2000 | 1600-2000 | 1600-2000 | 1600-2000 | 1600-2000 | 1600-2000 | 1600-2000 |

Dust Removal Efficiency (%) | ≥99 | ≥99 | ≥99 | ≥99 | ≥99 | ≥99 | ≥99 |

Water Filling Volume (m³) | 0.9 | 1.05 | 1.53 | 2.01 | 3.35 | 4.12 | 5.06 |

Overflow (kg/h) | 144 | 215 | 324 | 432 | 576 | 720 | 1008 |

Ash Discharge (kg/shift) | 900 | 1050 | 1530 | 2010 | 3350 | 4120 | 5660 |

Overall Dimensions (L*W*H) mm | 1600*930*3320 | 2000*930*3320 | 2000*1360*3400 | 2000*1790*3450 | 2850*1950*3560 | 2850*2400*3560 | 2850*3300*3560 |

Fan Model | 4-72No4.5A | 4-72No4.5A | 4-72No5A | 4-79No5A | 4-72No8C | G4-73No9D | G4-73No10D |

Total Pressure (Pa) | 2606 | 2408 | 2970 | 2910 | 2440 | 2660 | 3292 |

Airflow (m³/h) | 4800 | 7200 | 10800 | 14400 | 19200 | 24000 | 33600 |

Motor Model | Y132S2-2B35 | Y132S2-2B35 | Y160M2-2B35 | Y160M2-2B35 | Y180L-4 | Y200L-4 | Y250L-4 |

Power (kW) | 7.5 | 7.5 | 15 | 15 | 22 | 30 | 55 |

Rotational Speed (r/min) | 2900 | 2900 | 2900 | 2900 | 1600 | 1450 | 1450 |

Equipment Net Weight (kg) | 1408 | 1713 | 2113 | 2508 | 3322 | 3849 | 4743 |

Differential Pressure Transmitter | ● | ● | ● | ● | ● | ● | ● |

Electric Valve | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Solenoid Valve | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

●Standard Configuration ○Optional Configuration

Application

It is mainly used for the collection and treatment of flammable and low-ignition-point coal in the thermal power industry; it is also suitable for the washing and purification of various industrial dust, organic odors, acid and alkali waste gases, and other harmful gases. It is applicable to industries such as chemical pharmaceuticals, food processing, metallurgy, casting, carbon materials, machining, building materials, tablet presses, granulators, mixers, batching, mixing, and vibrating screens.

Multiclone dust collector manufacturer

JPAC focuses on providing high-quality multiclone dust collector and excellent service since 1982. We are a professional multiclone dust collector manufacturer and factory of 43000M2 which mainly produce central air conditioning units and dust collector products for around 44 years’ experience. JPAC provides you with multiclone dust collector wholesale, customization, design, packaging, industry solutions and OEM & ODM service.

Where to buy multiclone dust collector?

If you have any questions about multiclone dust collector, multi tube impact dust collector, please don't hesitate to contact us at logos@jsjpxhj.com. We will provide detailed information and technical support about central air conditioning units and dust collectors’ features, specifications, solutions and customization options... Welcome you to visit our factory!

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

ဗမာစာ

தமிழ்

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Eesti keel

Oʻzbekcha

latviešu

Български

ქართული

ગુજરાતી

Hausa

Basa Jawa

Lietuvių

Македонски

मराठी

ਪੰਜਾਬੀ

తెలుగు

Yorùbá