We're professional sintered plate dust collector manufacturers and suppliers in China, to buy or wholesale sinter-plate dust collector from our factory. For quotation or if you have any questions, contact us now for customized sintered plate dust collectors and price.

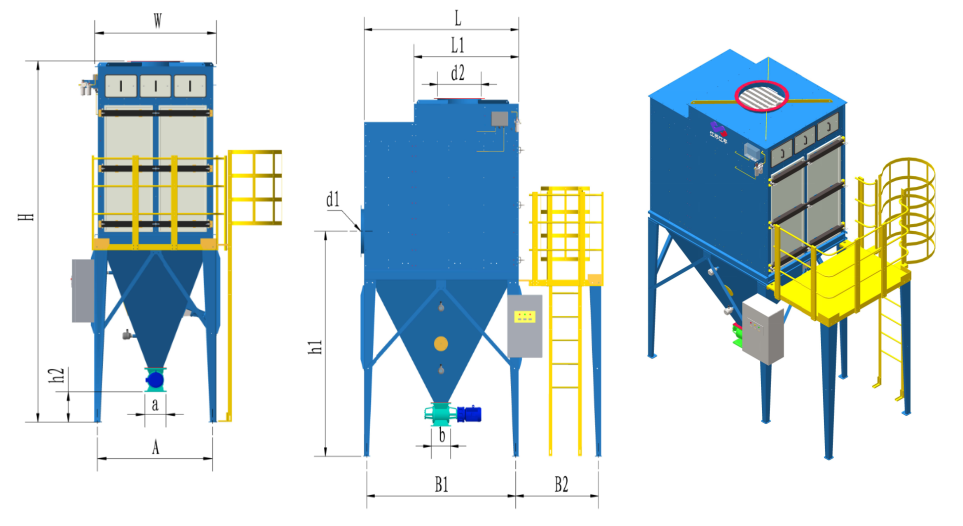

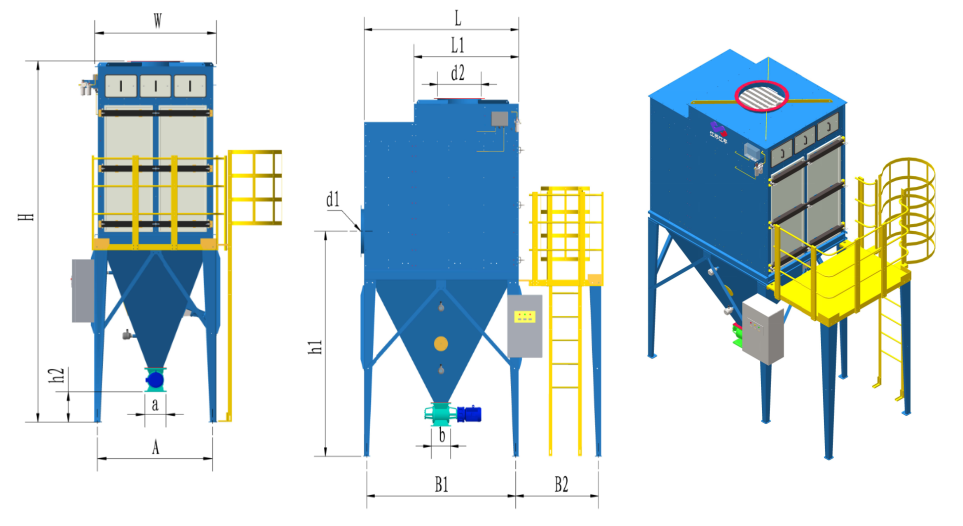

Appearance Reference

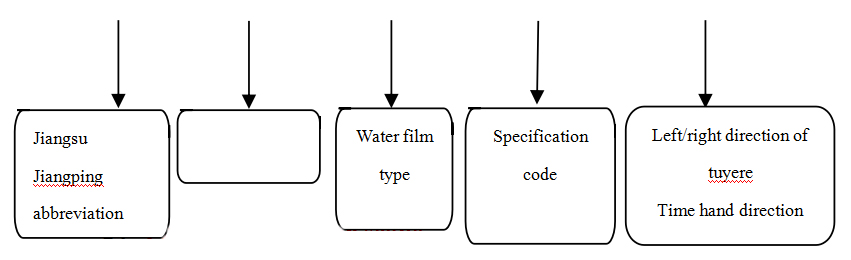

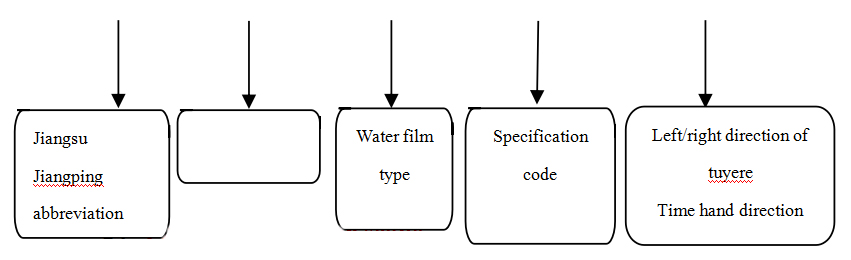

Symbolic Standard

Product Features

● High Dust Removal Efficiency: Under normal circumstances, the dust concentration in the exhaust gas of the dust collector can be maintained below 1 mg/m³. It can effectively capture ultrafine dust smaller than 2µm, with a dust removal efficiency of up to 99.99%, achieving ultra-low emissions.

● Stable Pressure Loss: The smooth surface of the sintered plastic plate makes it difficult for dust to pass through and remain. Clogging does not occur in the filter plate matrix layer. The pressure loss of the filter element stabilizes and remains constant after a very short time.

● Excellent Dust Removal Effect: The inertness of the resin and the smoothness of its surface make it almost impossible for powder to undergo physicochemical reactions or adhere to other substances. The pulsed airflow passes directly through the filter from the inside to the outside, and the dust is removed instantly.

● Strong Moisture Resistance: Due to the completely hydrophobic materials and coatings used to make the filter plates, they not only do not stick to dry dust, but also do not easily clump together with dust containing high moisture content. Therefore, sintered plastic plate dust collectors are very effective at handling dust with high moisture and oil content. In addition, they also have advantages such as antistatic properties, acid and alkali resistance, strong moisture resistance, wear resistance, long trouble-free operation time, and long service life.

● Long Service Life: The rigid structure of the sintered plastic plate eliminates the lifespan problems caused by skeleton wear of fibrous fabric filter media. Under some operating conditions, its service life is more than 10 times that of filter bags. Furthermore, the filter plates require no maintenance or upkeep. Even if the filter plates are damaged, they can be re-glued with special adhesive and continued to be used without any impact. The service life of domestically produced sintered plastic plates is 7-8 years, while imported sintered plastic plates have a service life of more than 10 years.

● Compact Dust Collector Structure: Because the surface shape of the filter plate is wavy, the unfolded surface area is 3 times the original surface area, thus the dust collector occupies a small area and saves space. The space occupied by sintered plastic plate dust collectors is only 1/3 to 1/6 that of baghouse dust collectors, and they can be stacked to further reduce the footprint.

● Comparison of the appearance of sintered plastic plate dust collectors and baghouse dust collectors: Installation and maintenance are convenient. Replacing sintered plastic plates is extremely convenient; simply open the dust collector's inspection door and tighten the two bolts securing the plate to complete the assembly of one filter plate. In daily production, almost no maintenance is required.

Technical Parameters

Product Model | JPCSO106 | JPCSO108 | JPCSO110 | JPCSP106 | JPCSP108 | JPCSP110 | JPCSP112 | JPCSQ106 | JPCSQ108 | JPCSQ110 | JPCSQ112 |

Airflow Rate (m³/h) | 676~1100 | 902~1466 | 1123~1825 | 1392~2262 | 1824~2964 | 2280~3705 | 2736~4446 | 2376~3861 | 3168~5148 | 3960~6435 | 4752~7722 |

Filtration Velocity (m/min) | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 |

Filter Area (m²) | 14.1 | 18.8 | 23.4 | 29 | 38 | 48 | 57 | 49.5 | 66 | 82.5 | 99 |

Resistance (Pa) | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 |

Fan Model | B4-72-No2.8A | B4-72-No2.9A | B4-72-No2.9A | B4-72-No3.6A | B4-72-No4A | B4-72-No4A | B4-72-No4A | B4-72N03.6A | B4-72-No4A | B4-72-No5A | B4-72-No4.5A |

Motor Model | Y90S-2 | Y90S-2 | Y90S-2 | Y100L-2 | Y100L-2 | Y112M2 | Y112M2 | Y100L-2 | Y132S1-2 | Y132S1-2 | Y132S2-2 |

Motor Power (kW) | 3 | 4 | 4 | 4 | 3 | 4 | 4 | 3 | 5.5 | 5.5 | 7.5 |

Air Consumption (Nm³/min) | 0.03 | 0.05 | 0.06 | 0.07 | 0.09 | 0.12 | 0.14 | 0.13 | 0.17 | 0.21 | 0.25 |

Body Dimensions (L1*W*H) mm | 1036*1036*2900 | 1036*1036*2900 | 1036*1036*2900 | 1036*1036*3900 | 1294*1036*3900 | 1294*1036*3900 | 1294*1036*3900 | 1036*1036*3900 | 1036*1036*3900 | 1036*1036*3900 | 1294*1036*3900 |

Inlet Diameter (d1) mm | 80 | 90 | 100 | 100 | 240 | 280 | 300 | 280 | 320 | 360 | 360 |

Height from Ground (h1) mm | 1624 | 1624 | 1624 | 1624 | 1624 | 1624 | 1624 | 1624 | 1624 | 1624 | 1624 |

Outlet Diameter (d2) mm | 80 | 90 | 100 | 100 | 240 | 300 | 320 | 300 | 300 | 380 | 380 |

Height from Ground (H) mm | 2900 | 2900 | 2900 | 3900 | 3900 | 3900 | 3900 | 3900 | 3900 | 3900 | 3900 |

Discharge Port Dimensions (a*b) mm | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 |

Height from Ground (h2) mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

Body Base Dimensions (A*B1) mm | 956*956 | 956*1214 | 956*1214 | 956*1214 | 956*1214 | 956*1214 | 956*1214 | 956*956 | 956*956 | 956*956 | 956*1214 |

Body Weight (T) | 0.5 | 0.5 | 0.6 | 0.7 | 0.8 | 0.8 | 0.9 | 0.8 | 0.9 | 0.9 | 1.1 |

Vibrator | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Rotary Valve | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Screw Conveyor | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Differential Pressure Transmitter | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Temperature Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Fire Sprinkler System | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Level Gauge | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Explosion Vent | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Audible and Visual Alarm | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Product Model | JPCSP210 | JPCSP212 | JPCSP214 | JPCSP216 | JPCSQ208 | JPCSQ210 | JPCSQ212 | JPCSQ214 | JPCSQ216 |

Airflow Rate (m³/h) | 4560~7410 | 5472~8892 | 6384~10374 | 7296~11856 | 6336~10296 | 7920~12870 | 9504~15444 | 10944~17784 | 12672~20592 |

Filtration Velocity (m/min) | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 |

Filter Area (m²) | 95 | 114 | 133 | 152 | 132 | 165 | 198 | 228 | 264 |

Resistance (Pa) | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 |

Fan Model | B5-51No4.5A | B5-51No4.5A | B5-51No4.5A | B4-72No5A | B4-72-No4.5A | B4-72-5A | B4-72-5A | B4-72-5A | B4-72-5A |

Motor Model | Y132S2-2 | Y132S2-2 | Y132S2-2 | Y160M2-2 | Y132S2-2 | Y160M2-2 | Y160M2-2 | Y160M2-2 | Y160M2-2 |

Motor Power (kW) | 7.5 | 7.5 | 7.5 | 15 | 7.5 | 15 | 15 | 15 | 15 |

Air Consumption (Nm³/min) | 0.24 | 0.28 | 0.33 | 0.35 | 0.33 | 0.42 | 0.50 | 0.57 | 0.66 |

Body Dimensions (L1*W*H) mm | 1496*1036*3913 | 1496*1294*3877 | 1496*1542*3924 | 1496*1542*3924 | 1496*1036*4413 | 1496*1036*4413 | 1496*1294*4377 | 1496*1542*4424 | 1496*1542*4424 |

Inlet Diameter (d1) mm | 360 | 400 | 420 | 450 | 420 | 480 | 500 | 560 | 560 |

Height from Ground (h1) mm | 2287 | 2251 | 2413 | 2413 | 2213 | 2213 | 2251 | 2413 | 2413 |

Outlet Diameter (d2) mm | 380 | 380 | 500 | 500 | 500 | 500 | 500 | 630 | 630 |

Height from Ground (H) mm | 3913 | 3877 | 3924 | 3924 | 4413 | 4413 | 4377 | 4424 | 4424 |

Discharge Port Dimensions (a*b) mm | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 |

Height from Ground (h2) mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

Body Base Dimensions (A*B1) mm | 956*1416 | 1214*1416 | 1462*1416 | 1462*1416 | 956*1416 | 956*1416 | 1214*1416 | 1462*1416 | 1462*1416 |

Body Weight (T) | 1.2 | 1.3 | 1.3 | 1.3 | 1.2 | 1.2 | 1.4 | 1.4 | 1.6 |

Vibrator | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Rotary Valve | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Screw Conveyor | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Differential Pressure Transmitter | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Temperature Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Fire Sprinkler System | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Level Gauge | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Explosion Vent | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Audible and Visual Alarm | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Product Model | JPCSP310 | JPCSP312 | JPCSP314 | JPCSP316 | JPCSQ310 | JPCSQ312 | JPCSQ314 | JPCSQ316 |

Airflow Rate (m³/h) | 6840~11115 | 8208~13338 | 9576~15561 | 10944~17784 | 11880~19305 | 14256~23166 | 16632~27027 | 19008~30888 |

Filtration Velocity (m/min) | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 |

Filter Area (m²) | 143 | 171 | 200 | 228 | 248 | 297 | 347 | 396 |

Resistance (Pa) | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 | 1500~2500 |

Fan Model | B4-72-5A | B4-79-5A | B4-79-5A | B4-79-5A | B4-72-5A | B4-72-6C | B4-72-8D | B4-72-8C |

Motor Model | Y160M2-2 | Y160M2-2 | Y160M2-2 | Y160M2-2 | Y160M2-2 | Y160L-4 | Y180M-4 | Y180M-4 |

Motor Power (kW) | 15 | 15 | 15 | 15 | 15 | 15 | 18.5 | 18.5 |

Air Consumption (Nm³/min) | 0.38 | 0.42 | 0.5 | 0.57 | 0.62 | 0.75 | 0.87 | 0.99 |

Overall Dimensions (L*W*H) mm | 2220*1036*4400 | 2220*1294*4512 | 2220*1542*4565 | 2220*1542*4565 | 2220*1036*4900 | 2220*1294*5012 | 2220*1542*5065 | 2220*1542*5065 |

Inlet Diameter (d1) mm | 450 | 480 | 500 | 560 | 560 | 660 | 740 | 740 |

Height from Ground (h1) mm | 2773 | 2886 | 2886 | 2870 | 2773 | 2886 | 2886 | 2870 |

Outlet Diameter (d2) mm | 500 | 500 | 500 | 630 | 560 | 700 | 800 | 800 |

Height from Ground (H) mm | 4400 | 4512 | 4565 | 4565 | 4900 | 5012 | 5065 | 5065 |

Discharge Port Dimensions (a*b) mm | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 |

Height from Ground (h2) mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

Base Dimensions (A*B1) mm | 956*2140 | 1214*2140 | 1462*2140 | 1462*2140 | 956*2140 | 1214*2140 | 1462*2140 | 1462*2140 |

Unit Weight (T) | 1.5 | 1.5 | 1.5 | 1.7 | 1.5 | 1.7 | 1.8 | 1.9 |

Vibrator | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Rotary Valve | ● | ● | ● | ● | ● | ● | ● | ● |

Screw Conveyor | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Differential Pressure Transmitter | ● | ● | ● | ● | ● | ● | ● | ● |

Temperature Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Fire Sprinkler System | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Level Gauge | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Explosion Vent | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Audible and Visual Alarm | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

●Standard Configuration ○Optional Configuration

Application

● Metal Smelting and Processing: High-temperature, high-concentration dust control in processes such as ironmaking, steelmaking, continuous casting, and hot rolling in steel plants; and dust control during the smelting of non-ferrous metals such as aluminum and copper.

● Chemical Industry: Sintered plate dust collectors effectively handle various acidic, alkaline, and sticky dusts generated during chemical reactions, drying, and packaging.

● Food Processing: Dust collection on production lines for puffed foods and baked goods, especially suitable for handling oily dust.

● Powder Metallurgy and Ceramics Industry: Sintered plate dust collectors effectively remove fine and hard dust particles during raw material preparation, forming, and sintering processes.

● Power Energy: Purification of flue gas from coal-fired power plant boilers, dust from biomass fuel combustion, and dust control from other new energy production equipment.

Sintered plate dust collector manufacturer

JPAC focuses on providing high-quality sintered plate dust collector and excellent service since 1982. We are a professional sintered plate dust collector manufacturer and factory of 43000M2 which mainly produce central air conditioning units and dust collector products for around 44 years’ experience. JPAC provides you with sintered plate dust collector wholesale, customization, design, packaging, industry solutions and OEM & ODM service.

Where to buy sintered plate dust collector?

If you have any questions about sintered plate dust collector, sinter-plate dust collector, sintered plate dust collectors, sintered plate filter dust collector, please don't hesitate to contact us at logos@jsjpxhj.com. We will provide detailed information and technical support about central air conditioning units and dust collectors’ features, specifications, solutions and customization options... Welcome you to visit our factory!

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

ဗမာစာ

தமிழ்

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Eesti keel

Oʻzbekcha

latviešu

Български

ქართული

ગુજરાતી

Hausa

Basa Jawa

Lietuvių

Македонски

मराठी

ਪੰਜਾਬੀ

తెలుగు

Yorùbá

Ultra fine silicon powder, 10000m³/h, solves the problems of bag shedding and excessive emissions

Ultra fine silicon powder, 10000m³/h, solves the problems of bag shedding and excessive emissions Pharmaceutical industry, coating machine dust removal, air volume 12000m³/h, emission concentration is less than 1mg/Nm³

Pharmaceutical industry, coating machine dust removal, air volume 12000m³/h, emission concentration is less than 1mg/Nm³