We're professional dry fog dust suppression system manufacturers and suppliers in China, to buy or wholesale dry fog dust suppression from our factory. For quotation or if you have any questions, contact us now for customized cold fog dust suppression system and price.

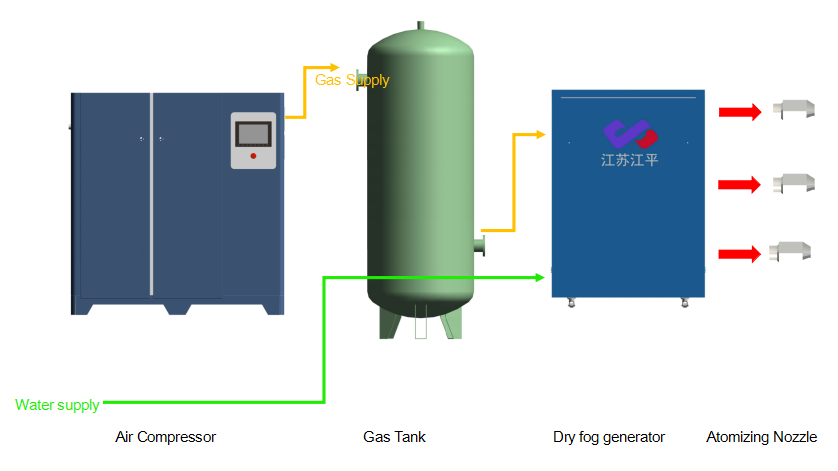

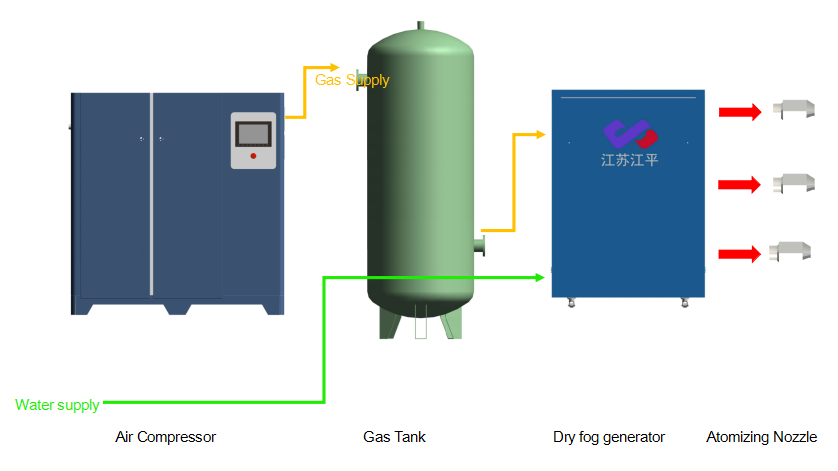

Appearance Reference

Features

High humidification efficiency, fine mist particles with an average diameter of 3-10μm, fast humidification speed, and even diffusion;

● Depending on the ambient temperature and humidity, the humidification efficiency can reach 70-90%, and the maximum humidification capacity of a single unit can reach 360 kg/h;

● If pure water is used, no white powder will be produced; there is no pollution to the environment; the nozzles can be combined arbitrarily, and the number of humidifiers or nozzles can be combined according to the required humidification capacity; it can easily provide regional humidification according to the user's special requirements, and has strong scalability;

● The overall design is simple and unique, with powerful functions. The electrical control system comes with a water/air control valve, which can adopt single-stage or multi-stage control according to actual conditions, or be connected to the control signals of on-site equipment for on-site control by PLC;

● In addition to humidification and dust reduction, it also has a cooling effect on factories or other places;

● Low operating cost, only about 1/20 of that of ordinary electric humidifiers, especially suitable for manufacturers with compressed air sources;

● Basically no consumables, low maintenance, and long service life.

Technical Parameters

Nozzle code | Injection model | air pressure | water pressure | Air flow rate (L/min) | Water flow rate (L/hr) | Average particle size (μm) | Spray distance (m) | Angle |

(bar) | (bar) | (°) |

A | SV882 | 5 | 1 | 240 | 20 | 7~10 | 3.5 | 60 |

B | SV980 | 3 | 0.5 | 307 | 45 | 4~10 | 4 | 30 |

Serial number | Atomizer Model | JPCGW-40 | JPCGW-65 | JPCGW-80 | JPCGW-100 |

Parameter |

1 | Maximum Design Air Consumption (m³/min) | < 10 | < 18 | < 30 | < 45 |

2 | Maximum Design Water Consumption (L/min) | < 10 | < 30 | < 50 | < 80 |

3 | Water Mist Particle Diameter (μm) | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 |

4 | Operating Ambient Temperature (°C) | -25~+50 | -25~+50 | -25~+50 | -25~+50 |

5 | Air Compressor Power (kW) | ≤ 22 | ≤ 45 | ≤ 55 | ≤ 2×45 |

6 | Air Storage Tank (m³) | ≤ 3 | ≤ 4 | ≤ 5 | ≤ 15 |

7 | Air Compressor Power Supply (V) | AC380 | AC380 | AC380 | AC380 |

8 | Atomizer Control Method | Automatic / Manual | Automatic / Manual | Automatic / Manual | Automatic / Manual |

9 | Anti-freezing Measures | Contains | Contains | Contains | Contains |

10 | Protection Class | IP55 | IP55 | IP55 | IP55 |

11 | Air Supply Pressure (MPa) | 0.7 | 0.8 | 0.8 | 0.8 |

12 | Water Supply Pressure (MPa) | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 |

13 | Suspended Solids in Water Supply (ppm) | ≤ 50 | ≤ 50 | ≤ 50 | ≤ 50 |

14 | Water Supply pH Value | 6~8 | 6~8 | 6~8 | 6~8 |

15 | Total Water Hardness (mg/L) | ≤ 450 | ≤ 450 | ≤ 450 | ≤ 450 |

16 | Chloride Content in Water Supply (mg/L) | ≤ 250 | ≤ 250 | ≤ 250 | ≤ 250 |

17 | Atomizer Weight (kg) | 260 | 400 | 500 | 500×2 |

18 | Atomizer Dimensions (L×W×H) mm | 1200×800×1200 | 1200×900×1200 | 1300×1000×1200 | 1300×1500×1300 |

19 | Explosion-proof Configuration | ○ | ○ | ○ | ○ |

20 | Constant Temperature Control | ○ | ○ | ○ | ○ |

Application

Widely applicable to large industrial plants or facilities, such as textile factories, printing plants, tobacco factories, wood processing plants, and special occasions involving flowers, gunpowder, and tea. It is also used for humidification in fresh-keeping warehouses, cold storage facilities, and central air conditioning units. It can also be used in coal mines, power plants, for applications such as rotary car dumpers, bucket wheel excavators, ship loaders, ship unloaders, truck unloading points, loading towers, transfer stations, crushing and screening belt systems, coal bunkers, impeller coal feeders, activated coal feeders, and mobile unloading trolleys.

Dry fog dust suppression system manufacturer

JPAC focuses on providing high-quality dry fog dust suppression system and excellent service since 1982. We are a professional dry fog dust suppression system manufacturer and factory of 43000M2 which mainly produce central air conditioning units and dust collector products for around 44 years’ experience. JPAC provides you with dry fog dust suppression system wholesale, customization, design, packaging, industry solutions and OEM & ODM service.

Where to buy dry fog dust suppression system?

If you have any questions about dry fog dust suppression system, dry fog dust suppression, cold fog dust suppression system, fogging system for dust control, dust suppression spray system, mist air dust suppression systems, water spray dust suppression system, please don't hesitate to contact us at logos@jsjpxhj.com. We will provide detailed information and technical support about central air conditioning units and dust collectors’ features, specifications, solutions and customization options... Welcome you to visit our factory!

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

ဗမာစာ

தமிழ்

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Eesti keel

Oʻzbekcha

latviešu

Български

ქართული

ગુજરાતી

Hausa

Basa Jawa

Lietuvių

Македонски

मराठी

ਪੰਜਾਬੀ

తెలుగు

Yorùbá