Facing dust control challenges in tight spaces? Air Box Pulse Bag Dust Collector provides a high-efficiency, modular Bag House Collector solution. Engineered for easy on-site assembly and corrosion resistance, it delivers reliable performance in cement, metallurgy, and chemical processing. Explore technical details and customization options below to find your ideal fit.

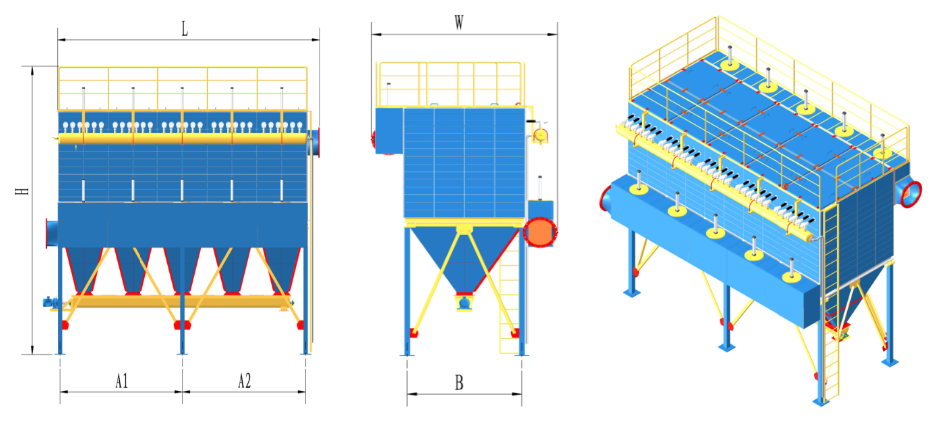

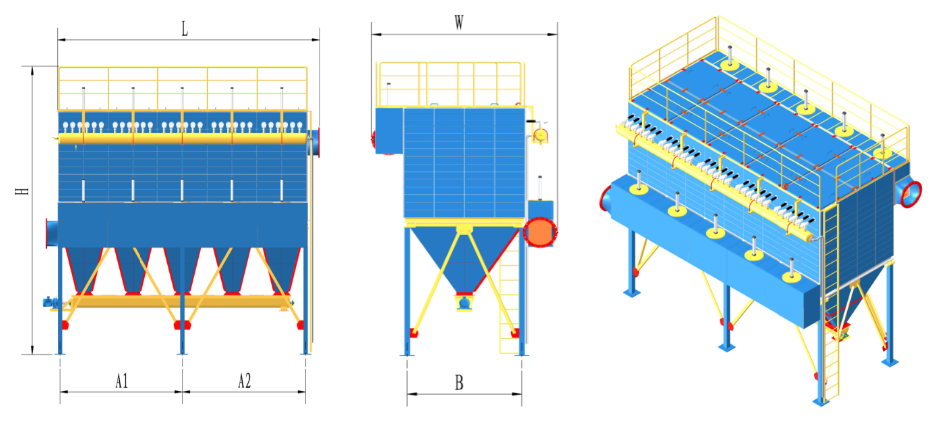

Appearance Reference

Working Principle

The dust collector is modular in design, flexible in assembly and wide in air handling range, with suitable models and combinations from 1000m3/h to 120000m3/h, and it is suitable for installation in various places with limited space.

Working principle: When the dust-containing gas enters the filter chamber through the tuyere and passes through the filter bag from outside to inside, the dust is retained on the outer surface of the filter bag, and the clean gas enters the bag and is discharged into the atmosphere from the outlet through the ejector and the clean chamber. When the dust on the surface of the filter bag continuously increases, resulting in the equipment resistance rising to the set value, the micro differential pressure controller has a signal output, and the controller sends a signal to make the injection system work. Compressed air is sprayed out through the outlet pipe, and is sprayed downward by the ejector at the speed of sound, forming a certain vacuum at the upper part of the ejector, and part of the air in the clean room is induced (called secondary air flow), which blows down the dust adhering to the outside of the filter bag and between fibers, so that the filter bag can be cleaned. The separated dust falls to the ash outlet and is discharged, and the filter bag is in the filtering state after the injection.

Advantage

The module is connected by bolts, eliminating the need for welding. It can be assembled on site, is easy to move and install, and is suitable for installation in narrow Spaces and inside high-rise buildings. Both the inner and outer surfaces of the box are treated with phosphating and high-pressure electrostatic spraying, which has strong anti-corrosion ability and is durable. The air inlet and outlet, maintenance ladder and ash unloading direction are multi-faceted and adjustable, facilitating system design and on-site installation. When the filtration area is greater than 100 square meters, the ash hopper of the dust collector can adopt a screw conveyor and ash discharge valve. The ash discharge valve of the ash hopper of the dust collector is standard equipment. Special requirements such as the material level gauge, fire sprinkler, explosion-proof pressure relief device, and heating and insulation of the ash hopper can be selected.

Technical Parameters

Product Model | JPC-PPC/W32-3 | JPC-PPC/W32-4 | JPC-PPC/W32-5 | JPC-PPC/W32-6 | JPC-PPC/W64-4 | JPC-PPC/W64-5 | JPC-PPC/W64-6 | JPC-PPC/W64-7 | JPC-PPC/W64-8 |

Airflow Rate (m³/h) | 6000 | 7500 | 10000 | 12000 | 16000 | 20000 | 24000 | 28000 | 31000 |

Filtration Velocity (m/min) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

Filter Material Specifications | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 |

Total Filtration Area (m²) | 96 | 128 | 160 | 192 | 256 | 320 | 384 | 448 | 512 |

Net Filtration Area (m²) | 64 | 96 | 128 | 160 | 192 | 256 | 320 | 384 | 458 |

Number of Dust Collector Columns | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

Number of Dust Collector Chambers | 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 |

Number of Filter Bags per Chamber | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 |

Total Number of Filter Bags | 96 | 128 | 160 | 192 | 256 | 320 | 384 | 448 | 512 |

Dust Collector Resistance (Pa) | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 |

Dust Collection Method | Ash collection hopper | Ash collection hopper | Ash collection hopper | Ash collection hopper | Ash collection hopper | Ash collection hopper | Ash collection hopper | Ash collection hopper | Ash collection hopper |

Compatible Motor (kW) | 11kw | 15kw | 18.5kw | 22kw | 30kw | 40kw | 45kw | 55kw | 55kw |

Inlet Gas Dust Concentration (g/Nm³) | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 |

Outlet Gas Dust Concentration (mg/Nm³) | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

Dust Removal Efficiency (%) | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 |

Air Leakage Rate (%) | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

Operating Temperature (°C) | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 |

Total Equipment Weight (kg) | 3000 | 3750 | 5000 | 6000 | 7500 | 9000 | 11000 | 13000 | 14500 |

Screw Conveyor | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Pneumatic Conveying | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Vibrating Motor | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Differential Pressure Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Temperature Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Fire Sprinkler System | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Level Gauge | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Explosion Venting Device | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Electric Heating and Insulation | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Product Model | JPC-PPC/W96-5 | JPC-PPC/W96-6 | JPC-PPC/W96-7 | JPC-PPC/W96-8 | JPC-PPC/W96-9 | JPC-PPC/W96-2×5 | JPC-PPC/W96-2×6 | JPC-PPC/W96-2×7 | JPC-PPC/W96-2×8 | JPC-PPC/W96-2×9 | JPC-PPC/W96-2×10 |

Airflow Rate (m³/h) | 30000 | 35000 | 42000 | 47000 | 53000 | 59000 | 70000 | 82000 | 95000 | 110000 | 120000 |

Filtration Velocity (m/min) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

Filter Material Specifications | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 |

Total Filtration Area (m²) | 480 | 576 | 672 | 768 | 864 | 960 | 1152 | 1344 | 1536 | 1728 | 1920 |

Net Filtration Area (m²) | 384 | 480 | 576 | 472 | 768 | 864 | 1056 | 1248 | 1440 | 1632 | 1824 |

Number of Dust Collector Columns | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

Number of Dust Collector Chambers | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 |

Number of Filter Bags per Chamber | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 |

Total Number of Filter Bags | 480 | 576 | 672 | 768 | 864 | 960 | 1152 | 1344 | 1536 | 1728 | 1920 |

Dust Collection Method | Ash hopper collects ash. | Ash hopper collects ash. | Ash hopper collects ash. | Ash hopper collects ash. | Ash hopper collects ash. | Ash hopper collects ash. | Ash hopper collects ash. | Ash hopper collects ash. | Ash hopper collects ash. | Ash hopper collects ash. | Ash hopper collects ash. |

Dust Collector Resistance (Pa) | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 |

Compatible Motor (kW) | 45kw | 55kw | 75kw | 90kw | 110kw | 110kw | 132kw | 160kw | 185kw | 200kw | 250kw |

Inlet Gas Dust Concentration (g/Nm³) | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 |

Outlet Gas Dust Concentration (mg/Nm³) | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

Dust Removal Efficiency (%) | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 |

Air Leakage Rate (%) | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

Operating Temperature (°C) | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 |

Total Equipment Weight (kg) | 12000 | 14500 | 19600 | 22000 | 25000 | 27500 | 32600 | 38000 | 44300 | 51300 | 56000 |

Screw Conveyor | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Scraper Conveyor | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Pneumatic Conveying Device | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Humidifying Granulator | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Vibrating Motor | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Differential Pressure Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Temperature Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Fire Sprinkler System | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Level Gauge | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Explosion Venting Device | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Electric Heating and Insulation | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Product Model | JPC-PPW128-2×6 | JPC-PPW128-2×7 | JPC-PPW128-2×8 | JPC-PPW128-2×9 | JPC-PPW128-2×10 | JPC-PPW128-2×11 | JPC-PPW128-2×12 | JPC-PPW128-2×13 | JPC-PPW128-2×14 |

Airflow Rate (m³/h) | 95000 | 110000 | 128000 | 141000 | 158000 | 172000 | 190000 | 205000 | 230000 |

Filtration Velocity (m/min) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

Filter Material Specifications | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 |

Total Filtration Area (m²) | 1580 | 1833 | 2048 | 2304 | 2560 | 2816 | 3072 | 3328 | 3584 |

Net Filtration Area (m²) | 1408 | 1664 | 1920 | 2176 | 2432 | 2688 | 2920 | 3176 | 3432 |

Number of Dust Collector Columns | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

Number of Dust Collector Chambers | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

Number of Filter Bags per Chamber | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 |

Total Number of Filter Bags | 1536 | 1792 | 2048 | 2304 | 2560 | 2816 | 3072 | 3328 | 3584 |

Dust Collector Resistance (Pa) | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 |

Dust Collection Method | Ash collection hopper | Ash collection hopper | Ash collection hopper | Ash collection hopper | Ash collection hopper | Ash collection hopper | Ash collection hopper | Ash collection hopper | Ash collection hopper |

Compatible Motor (kW) | 110KW | 132KW | 160KW | 160KW | 185KW | 200KW | 220KW | 250KW | 280KW |

Inlet Gas Dust Concentration (g/Nm³) | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 |

Outlet Gas Dust Concentration (mg/Nm³) | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

Dust Removal Efficiency (%) | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 | 99.99 |

Air Leakage Rate (%) | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

Operating Temperature (°C) | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 |

Total Equipment Weight (kg) | 44000 | 52000 | 60000 | 65800 | 74000 | 80000 | 88000 | 96000 | 107000 |

Screw Conveyor | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Scraper Conveyor | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Pneumatic Conveying Device | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Humidifying Granulator | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Vibrating Motor | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Differential Pressure Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Temperature Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Fire Sprinkler System | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Level Gauge | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Explosion Venting Device | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Electric Heating and Insulation | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

●Standard Configuration ○Optional configuration

Application

It is widely applied in the dust collection systems of crushing, packaging, silo tops, clinker coolers and various mills in cement plants, and is also used for dust collection of waste gas in metallurgy, chemical industry, machinery and civil boilers.

Bag house dust collector manufacturer

JPAC focuses on providing high-quality bag house dust collector and excellent service since 1982. We are a professional bag house dust collector manufacturer and factory of 43000M2 which mainly produce central air conditioning units and dust collector products for around 44 years’ experience. JPAC provides you with bag house dust collector wholesale, customization, design, packaging, industry solutions and OEM & ODM service.

Where to buy bag house dust collector?

If you have any questions about bag house dust collector, bag dust collector, bag type dust collector, please don't hesitate to contact us at logos@jsjpxhj.com. We will provide detailed information and technical support about central air conditioning units and dust collectors’ features, specifications, solutions and customization options... Welcome you to visit our factory!

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

ဗမာစာ

தமிழ்

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Eesti keel

Oʻzbekcha

latviešu

Български

ქართული

ગુજરાતી

Hausa

Basa Jawa

Lietuvių

Македонски

मराठी

ਪੰਜਾਬੀ

తెలుగు

Yorùbá