Handling combustible dust? Our Explosion Proof Dust Collector is engineered as a reliable ex proof dust collection system to mitigate explosion risks. Featuring robust construction and safety compliance, it ensures secure operations in chemical, pharmaceutical, and grain processing. Explore design specs, safety certifications, and industry solutions below to protect your facility.

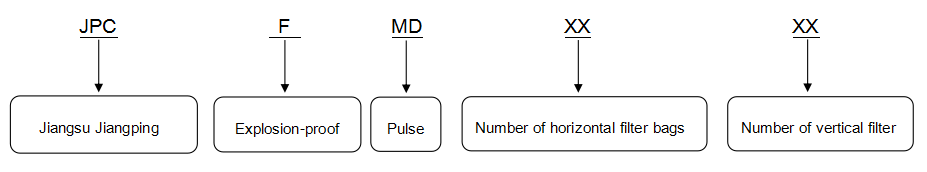

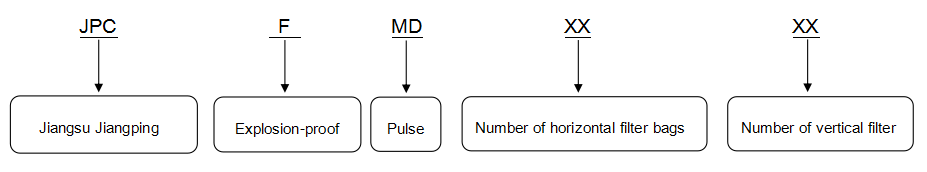

Symbol Standard

Features

Utilizing high-precision laser processing equipment and environmentally friendly electrostatic powder coating, the integrated dust collector requires no welding; it is assembled by bolts and riveting, making it suitable for assembly in confined spaces. It boasts high strength, excellent sealing, high efficiency, an attractive appearance, and durable construction. For engineering renovation projects, it simplifies the process, shortens the construction period, and reduces construction costs and risks.

Application

It is widely used in explosion-proof and flameproof areas such as mines, chemical plants, coal mines, building materials, metallurgy, power plants, steel plants, and docks, as well as in occasions requiring air purification and environmental management.

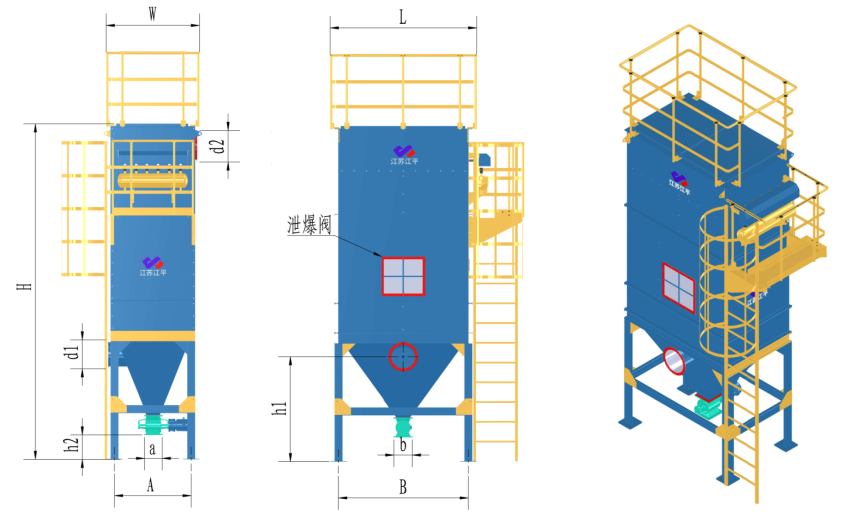

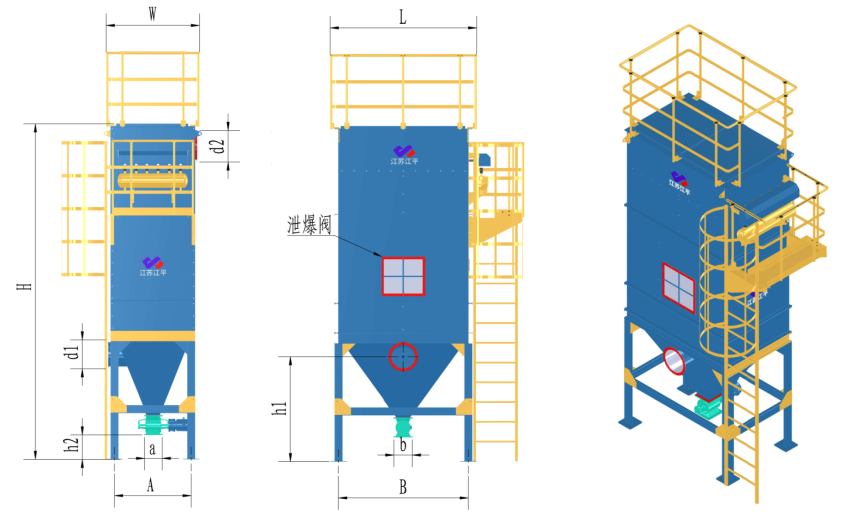

Appearance reference

Appearance reference

Technical Parameters

Model Type | JPCFMD0608 | JPCFMD0610 | JPCFMD0612 | JPCFMD0812 | JPCFMD1012 | JPCFMD1212 | JPCFMD1612 | JPCFMD2012 | JPCFMD2412 | JPCFMD2812 | JPCFMD3212 |

Airflow Rate (m³/h) | 3600 | 4000 | 4500 | 5760 | 7200 | 8640 | 11520 | 14400 | 17280 | 20160 | 23040 |

Airflow Range (m³) | 2304-4320 | 2880-5400 | 3456-6480 | 4608-8640 | 5760-10800 | 6912-12960 | 9216-17280 | 11520-21600 | 13824-25920 | 16128-30240 | 18432-34560 |

Filter Area (m²) | 48 | 60 | 72 | 96 | 120 | 144 | 192 | 240 | 288 | 336 | 384 |

Filtration Velocity (m/min) | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 | 0.8-1.3 |

Equipment Resistance (Pa) | <1200 |

Dust Removal Efficiency (%) | 99.9 |

Inlet Dust Concentration (g/m³) | <30 |

Number of Pulse Valves | 6 | 6 | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 28 | 32 |

Pulse Valve Specifications | DN25 | DN25 | DN25 | DN25 | DN25 | DN25 | DN25 | DN25 | DN25 | DN25 | DN25 |

Air Consumption (m³/min) | 0.4 | 0.4 | 0.4 | 0.5 | 0.6 | 0.7 | 0.9 | 1 | 1.2 | 1.4 | 1.5 |

Fan | Fan model | B4-72No3.6A | B4-72No4A | B4-72No4A | B4-79No4A | B4-72No4.5A | B4-72-No5A | B4-72No6C | B4-72No6C | B4-72No8C | B4-72No8C | B4-72No8C |

Airflow (m³/h) | 2304-4320 | 2880-5400 | 3456-6480 | 4608-8640 | 5760-10800 | 6912-12960 | 9216-17280 | 11520-21600 | 13824-25920 | 16128-30240 | 18432-34560 |

Rotational speed (r/min) | 2900 | 2900 | 2900 | 2900 | 2900 | 2900 | 2240 | 1600 | 1800 | 1600 | 1800 |

Motor power (kW) | Y160L-2(3KW) | Y132S1-2(5.5kw) | Y132S1-2(5.5kw) | Y132S1-2(5.5kw) | Y132S2-2(7.5kw) | Y160M2-2(15kw) | Y160L-4(15kw) | Y160L-4(15kw) | Y180M-4(18.5kw) | Y180M2(30kw) | Y200L1-2(30KW) |

Ash discharge valve power (kW) | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | 0.75 | 0.75 | 0.75 |

Screw conveyor power (kW) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 |

Filter bag operating temperature (°C) | ≤130 |

Filter bag specifications (mm) | Φ130*2500 |

Model Number | JPCFMD0608 | JPCFMD0610 | JPCFMD0612 | JPCFMD0812 | JPCFMD1012 | JPCFMD1212 | JPCFMD1612 | JPCFMD2012 | JPCFMD2412 | JPCFMD2812 | JPCFMD3212 |

Overall Dimensions (L*W*H) mm | 1900*1120*4900 | 1900*1290*4900 | 1900*1290*4900 | 2070*1290*5050 | 1900*1900*4900 | 2240*1900*5200 | 2410*2070*5350 | 2920*2410*5590 | 3530*2410*5590 | 4140*2410*5590 | 4650*2410*5700 |

Air Inlet Diameter (d1) mm | 320 | 360 | 360 | 360 | 420 | 420 | 450 | 500 | 560 | 630*500 | 720*500 |

Height from Ground (h1) mm | 1450 | 1430 | 1430 | 1580 | 1400 | 1700 | 1835 | 2040 | 2010 | 2040 | 2150 |

Air Outlet Diameter (d2) mm | 360 | 400 | 400 | 400 | 450 | 450 | 500 | 500 | 630*500 | 1000*500 | 1000*500 |

Equipment Height (H) mm | 4600 | 4600 | 4600 | 5050 | 5050 | 4900 | 5050 | 5290 | 5290 | 5290 | 5400 |

Discharge Port Dimensions (a*b) mm | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 |

Height from Ground (h2) mm | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

Base Dimensions (A*B) mm | 1000*1780 | 1170*1780 | 1780*1170 | 1950*1170 | 1780*1780 | 2120*1780 | 2290*1950 | 2800*2290 | 3410*2290 | 4020*2290 | 4530*2290 |

Screw Conveyor | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Differential Pressure Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Temperature Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Fire Sprinkler System | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Level Gauge | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Explosion Vent | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Explosion Isolation Valve | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Audible and Visual Alarm | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Equipment Weight (kg) | 3000 | 3200 | 3400 | 3650 | 3900 | 4200 | 4600 | 4950 | 5400 | 5850 | 6400 |

●Standard configuration ○Optional configuration

Explosion Proof Dust Collector manufacturer

JPAC focuses on providing high-quality bag house dust collector and excellent service since 1982. We are a professional bag house dust collector manufacturer and factory of 43000M2 which mainly produce central air conditioning units and dust collector products for around 44 years’ experience. JPAC provides you with bag house dust collector wholesale, customization, design, packaging, industry solutions and OEM & ODM service.

Where to buy bag house dust collector?

If you have any questions about explosion proof dust collector, explosion proof dust collectors, explosion proof dust collection systems, please don't hesitate to contact us at logos@jsjpxhj.com. We will provide detailed information and technical support about central air conditioning units and dust collectors’ features, specifications, solutions and customization options... Welcome you to visit our factory!

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

ဗမာစာ

தமிழ்

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Eesti keel

Oʻzbekcha

latviešu

Български

ქართული

ગુજરાતી

Hausa

Basa Jawa

Lietuvių

Македонски

मराठी

ਪੰਜਾਬੀ

తెలుగు

Yorùbá