Need a dust collector that’s easier to service? Flat Bag Dust Collector provides a practical bag type dust collector solution with its accessible filter design and 99.8% efficiency. It’s built for demanding environments in cement, woodworking, and powder processing. Review the technical specifications and configurations below to optimize your system.

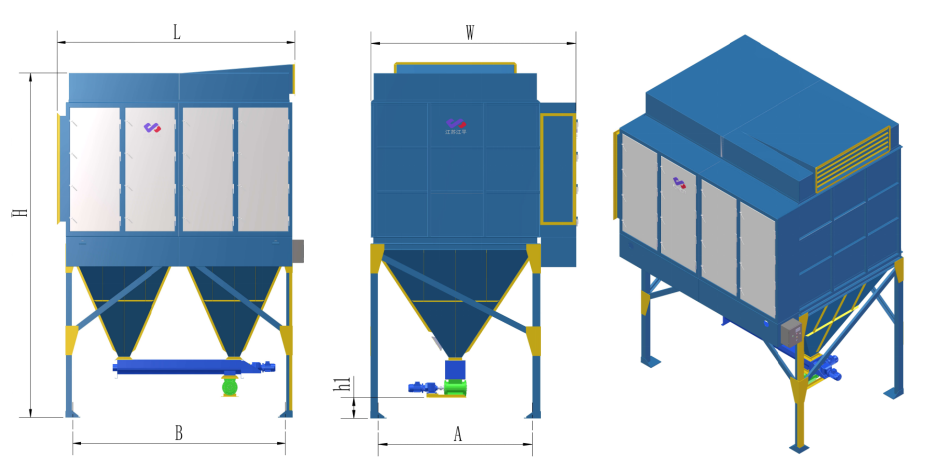

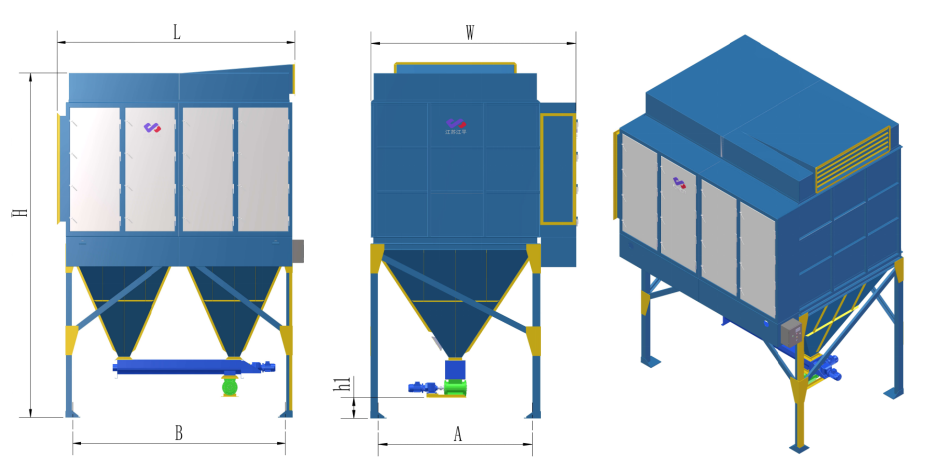

Appearance Reference

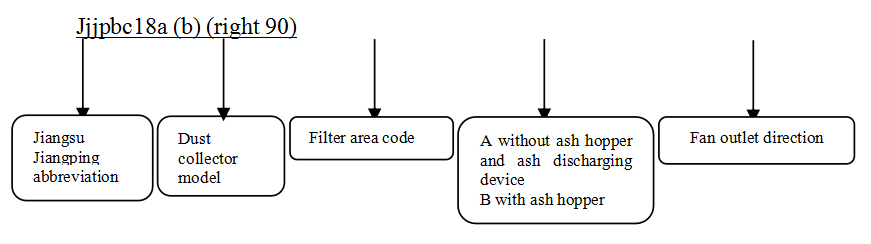

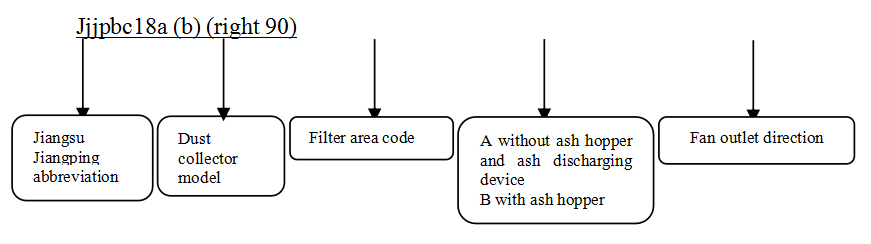

Symbol Standard

Features

● Flat bag dust collectors occupy less space than round bag dust collectors for the same filtration area.

● They are suitable for confined spaces and conveyor belts.

● They also offer advantages such as high strength, good heat resistance, acid and alkali resistance, moisture resistance, and long service life.

Structure and Working Principle

1, dust collector structure

This unit is composed of fan, filter box, frame flat cloth bag, ash cleaning and vibrating mechanism, hopper and ash discharging device, which can work automatically according to program control.

2. Working principle

When the machine is started, the negative pressure in the dust filter chamber is caused by the fan, so that the dust-containing gas is sucked into the filter box from the air inlet, filtered by the cloth bag and attached to the outside of the cloth bag, and the clean air enters the purification chamber through the filter material and is sent to the outdoor atmosphere by the fan, thereby achieving the purpose of purifying the air or collecting solid particles in the dust-containing gas.

With the operation of the unit, the dust attached to the outer wall of the bag slowly increases, and the negative force of the unit rises sharply. Due to the function of the differential pressure alarm, the fan stops and the mechanical rapping ash cleaning mechanism starts to work, forcing the accumulated ash to fall, and the ash hopper is discharged through the hopper and the ash discharging hopper device. After a set time, the rapping motor stops working, which completes an ash cleaning cycle.

Technical Parameters

Product Model | JPCBC-18 | JPCBC-23 | JPCBC-28 | JPCBC-36 | JPCBC-45 | JPCBC-56 |

Airflow Rate (m³/h) | 2210 | 3284 | 4000 | 5700 | 7560 | 10080 |

Filtration Velocity (m/min) | 2.05 | 2.38 | 2.8 | 2.64 | 2.8 | 3 |

Filtration Area (㎡) | 18 | 23 | 28 | 36 | 45 | 56 |

Equipment Resistance (Pa) | ﹤900 | ﹤1000 | ﹤1000 | ﹤1000 | ﹤1000 | ﹤1000 |

Dust Removal Efficiency (%) | >99 | >99 | >99 | >99 | >99 | >99 |

Number of Filter Bags | 16 | 21 | 25 | 32 | 42 | 50 |

Inlet Dust Concentration (g/m³) | ﹤30 | ﹤30 | ﹤30 | ﹤30 | ﹤30 | ﹤30 |

Gas Temperature (°C) | ﹤120 | ﹤120 | ﹤120 | ﹤120 | ﹤120 | ﹤120 |

Air Leakage Rate (%) | ﹤3 | ﹤3 | ﹤3 | ﹤3 | ﹤3 | ﹤3 |

Centrifugal Fan Model | 4-72No3.2A | 4-72No3.6A | 4-72No4A | 4-72No4.5A | 4-72No4.5A | 4-72No5A |

Airflow Rate (m³/h) | 1975-3517 | 2930-5268 | 4020-7419 | 5720-10560 | 5720-10560 | 7280-15455 |

Air Pressure (Pa) | 1270-792 | 1578-989 | 2040-1320 | 2580-1673 | 2580-1673 | 3187-2019 |

Rotational Speed (m/min) | 2900 | 2900 | 2900 | 2900 | 2900 | 2900 |

Motor Model | Y90L-2 | Y100L-2 | Y132S1-2 | Y132S2-2 | Y132S2-2 | Y160M2-2 |

Motor Power (kW) | 2.2 | 3 | 5.5 | 7.5 | 7.5 | 15 |

Vibrating Motor Power (kW) | 0.18 | 0.18 | 0.18 | 2*0.18 | 2*0.18 | 2*0.18 |

Ash Discharge Valve | ● | ● | ● | ● | ● | ● |

Differential Pressure Transmitter | ○ | ○ | ○ | ○ | ○ | ○ |

Temperature Transmitter | ○ | ○ | ○ | ○ | ○ | ○ |

Fire Sprinkler System | ○ | ○ | ○ | ○ | ○ | ○ |

Level Gauge | ○ | ○ | ○ | ○ | ○ | ○ |

Explosion Venting Device | ○ | ○ | ○ | ○ | ○ | ○ |

Explosion Isolation Valve | ○ | ○ | ○ | ○ | ○ | ○ |

Equipment Dimensions (L*W*H) mm | 974*850*1763 | 1219*850*1829 | 1415*850*1895 | 1694*974*1998 | 1694*1219*1998 | 1694*1415*2080 |

Control Box Dimensions (L*W*H) mm | 500*250*800 | 500*250*800 | 500*250*800 | 500*250*800 | 500*250*800 | 500*250*800 |

Equipment Weight (kg) | 480 | 630 | 690 | 840 | 1260 | 1380 |

●Standard Configuration ○Optional Configuration

Application

The equipment has a compact structure, is easy to operate, maintain, and control. The filter bags use polyester as the filter material and are mainly suitable for industries such as mining, chemical, coal, building materials, metallurgy, power, and ceramics.

Bag house dust collector manufacturer

JPAC focuses on providing high-quality bag house dust collector and excellent service since 1982. We are a professional bag house dust collector manufacturer and factory of 43000M2 which mainly produce central air conditioning units and dust collector products for around 44 years’ experience. JPAC provides you with bag house dust collector wholesale, customization, design, packaging, industry solutions and OEM & ODM service.

Where to buy bag house dust collector?

If you have any questions about bag house dust collector, baghouse dust collector, bag dust collector, please don't hesitate to contact us at logos@jsjpxhj.com. We will provide detailed information and technical support about central air conditioning units and dust collectors’ features, specifications, solutions and customization options... Welcome you to visit our factory!

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

ဗမာစာ

தமிழ்

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Eesti keel

Oʻzbekcha

latviešu

Български

ქართული

ગુજરાતી

Hausa

Basa Jawa

Lietuvių

Македонски

मराठी

ਪੰਜਾਬੀ

తెలుగు

Yorùbá