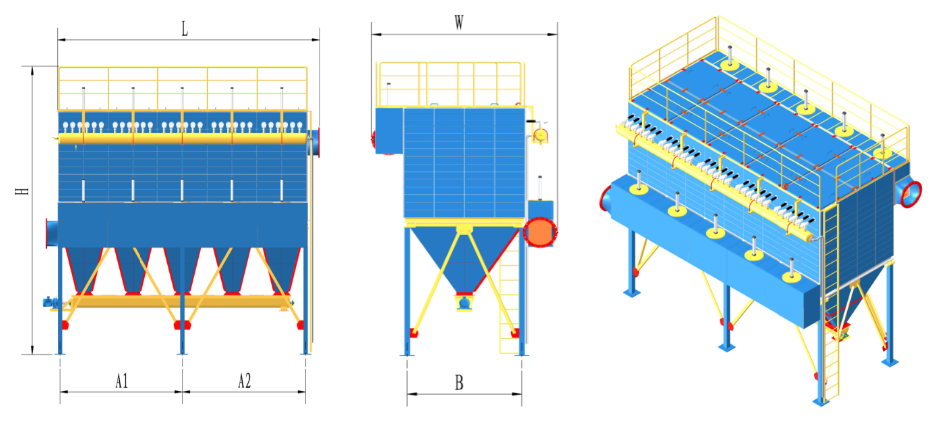

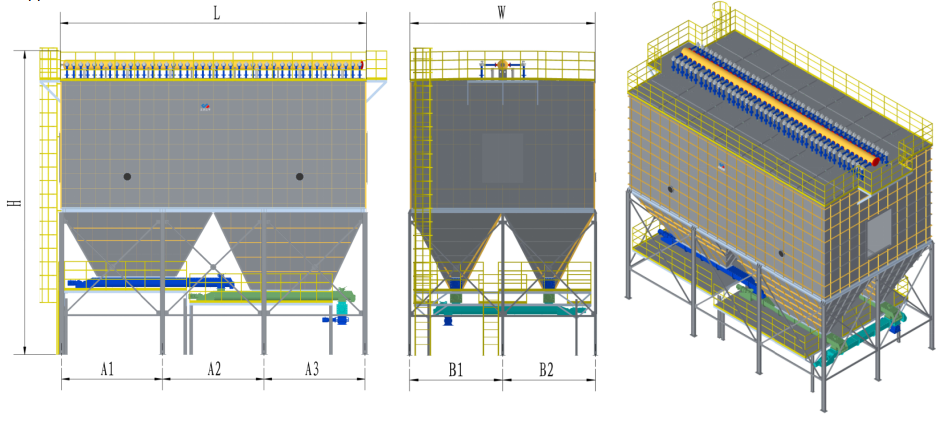

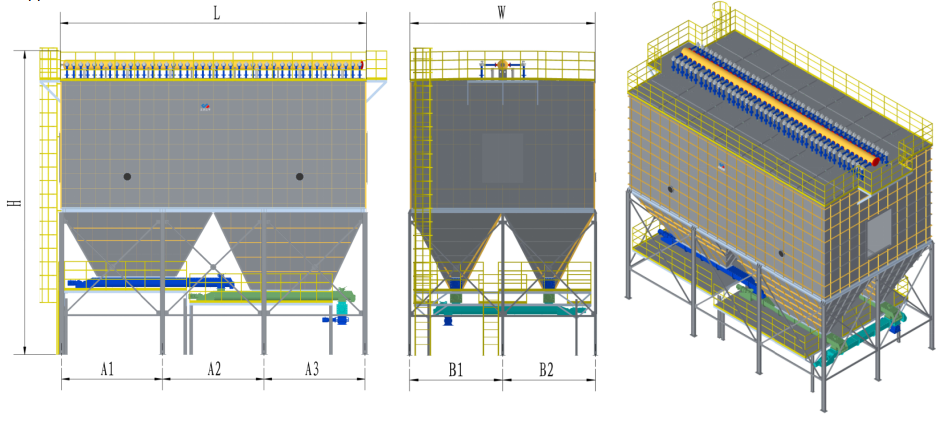

Appearance reference of long bag low pressure pulse bag dust collector

Overall Structure

This dust removal unit is composed of air inlet chamber, ash discharge chamber, filter chamber, clean air chamber, fan, and injection ash cleaning device.

Pulse cleaning adopts PLC control system, and the time is selected. The pressure difference control can also be realized according to the user's requirements. Controlled by PLC, use compressed air to clean the ash. The control mode is online control.

process flow

Source of pollution → hood collection → exhaust of branch air duct → exhaust of main air duct → filtration of dust collector → power fan → exhaust.

Working Principle

With the extension of filtration time, the dust layer on the filter bag keeps accumulating, and the resistance of the dust removal equipment keeps rising. When the resistance of the equipment rises to the set value, the dust removal device begins to clean the dust.When it is turned on, compressed air expands rapidly in the upper box in a very short time and flows into the filter bag, causing the filter bag to expand and deform to generate vibration, and under the action of reverse airflow scouring, the dust attached to the outer surface of the filter bag is stripped and falls into the ash hopper. After cleaning, the electromagnetic pulse valve is closed, and the chamber returns to the normal filtering state. Each chamber is cleaned in turn, from the first chamber to the next one. The treated flue gas is discharged into the atmosphere through the chimney, and the treated particles are sent to the silo after centralized treatment by pneumatic conveying equipment, and then transported by car through humidification granulation and bulk machine.

Product Features

The long-bag pulse dust collector features the strong dust cleaning capacity, high dust removal efficiency and low emission concentration of the jet pulse dust collector. It is also stable and reliable, with low energy consumption, and is suitable for treating large volumes of flue gas.

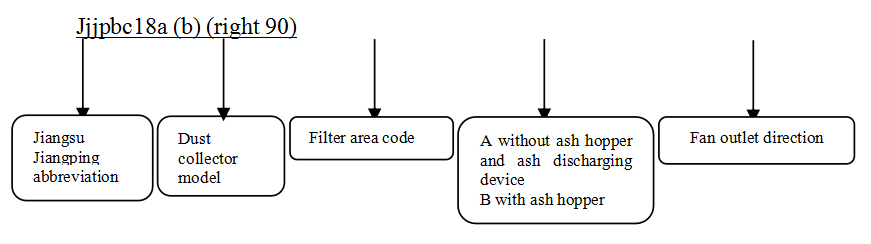

Description of type selection

1. Filter the wind speed

The selection of filtration wind speed of bag filter is closely related to the operation state of the equipment. For dusty gas with fine particles, high concentration, high viscosity and high moisture content, it should be selected according to low filtration wind speed, otherwise the filtration wind speed can be appropriately increased.

2. Conventional filter materials and conventional models can be used in general middle temperature areas (20-160℃).

3. For the high humidity environment, the temperature of gas in the dust collector and its system must be kept 25 ~ 35℃ higher than its dew point (for example, the dew point temperature of the kiln grinding machine should be generally controlled at 58℃, and the operating temperature should be generally controlled above 90℃) to ensure the good use effect of the filter bag.

Application of long bag low pressure pulse bag dust collector

It is widely applied in fields such as steelmaking electric furnaces, boilers, calcium carbide furnaces, purification of blast furnace gas, coal powder preparation and pneumatic conveying, asphalt concrete production, carbon black, building materials, refractory materials, chemical industry, aluminum electrolysis, and aluminum-zinc smelting.

Technical Parameters

Product Model | JPC-LDMC-1850 | JPC-LDMC-2300 | JPC-LDMC-2800 | JPC-LDMC-3700 | JPC-LDMC-4600 | JPC-LDMC-5500 | JPC-LDMC-6500 |

Filtering Area (m²) | 1850 | 2300 | 2800 | 3700 | 4600 | 5500 | 6500 |

Airflow Rate × 10⁴ (m³/h) | 16.2 | 20.7 | 25.2 | 33.3 | 41.4 | 49.5 | 58.5 |

Number of Filter Bags | 616 | 770 | 924 | 1232 | 1540 | 1848 | 2156 |

Filter Bag Specifications (mm) | φ160×6050 | φ160×6050 | φ160×6050 | φ160×6050 | φ160×6050 | φ160×6050 | φ160×6050 |

Cleaning Method | Offline dust removal | Offline dust removal | Offline dust removal | Offline dust removal | Offline dust removal | Offline dust removal | Offline dust removal |

Number of Offline Compartments | 4 | 5 | 6 | 8 | 10 | 12 | 14 |

Leakage Rate (%) | ≤2% | ≤2% | ≤2% | ≤2% | ≤2% | ≤2% | ≤2% |

Inlet Concentration (g/m³) | ≤30 | ≤30 | ≤30 | ≤30 | ≤30 | ≤30 | ≤30 |

Emission Concentration (mg/m³) | 5~10 | 5~10 | 5~10 | 5~10 | 5~10 | 5~10 | 5~10 |

Number of Pulse Valves | 44 | 55 | 66 | 88 | 110 | 132 | 154 |

Temperature Resistance (°C) | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 | ≤180 |

Reference Weight (T) | 72 | 91 | 110 | 145 | 175 | 210 | 250 |

Vibrating Motor | ● | ● | ● | ● | ● | ● | ● |

Differential Pressure Transmitter | ● | ● | ● | ● | ● | ● | ● |

Temperature Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Fire Sprinkler System | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Level Gauge | ● | ● | ● | ● | ● | ● | ● |

Explosion Venting Device | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Explosion Isolation Valve | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Audible and Visual Alarm | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Screw Conveyor | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Scraper Conveyor | ● | ● | ● | ● | ● | ● | ● |

Pneumatic Conveying System | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

COD Online Monitoring System | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Ash Storage Silo | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Humidifying Granulator | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Overall Dimensions L×W×H (mm) | 11500×5500×13800 | 3800×5500×13800 | 6560×5500×13800 | 22080×5500×13800 | 27600×5500×13800 | 33120×5500×13800 | 38640×5500×13800 |

●Standard Configuration ○Optional configuration

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

ဗမာစာ

தமிழ்

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Eesti keel

Oʻzbekcha

latviešu

Български

ქართული

ગુજરાતી

Hausa

Basa Jawa

Lietuvių

Македонски

मराठी

ਪੰਜਾਬੀ

తెలుగు

Yorùbá